Saint Peter High School students in Mr. Pehrson’s Intro to Metalworking class had an interesting welding experience recently, which proved to be a “tasty” alternative to their normal shop activities by improvising using, of all things, graham crackers and frosting!

“Our welding booth exhaust system for our welding booths was out of commission recently, and in the meantime what else can you do in a metalworking class when you are unable to weld?” Pehrson said. “We have learned many skills working with forging, bending, and letter punching pop cans creating different designs and art, which are a few of the projects we have done so far. The latest project that we are doing to still learn the techniques and processes while making it fun along the way.

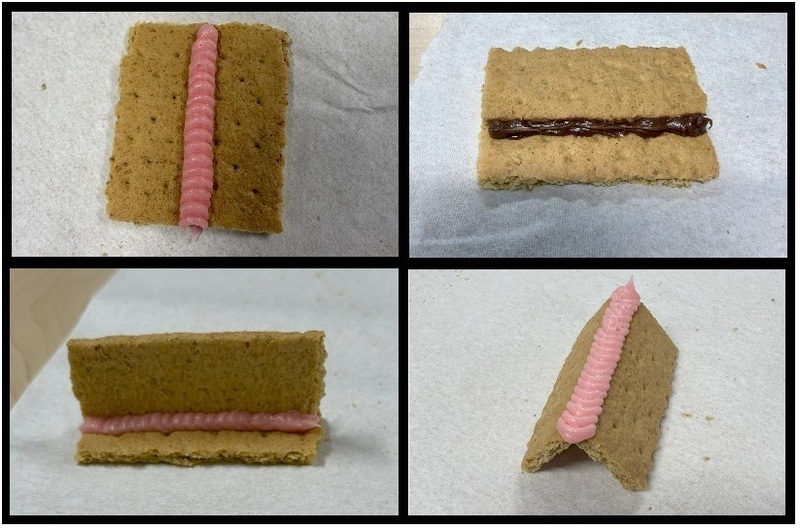

“Students were tasked to ‘weld’ four different joint types: Butt joint, Lap joint, "T" joint, and Outside corner joint. What better way to do that than with graham crackers and frosting to simulate the joints that are done on metal in the shop within the class.”

According to Pehrson, with the frosting welds you can see the same consistency variables and technique variables you would see in the shop and he can evaluate what is happening with each weld and how that directly correlates to the welding process.

“No graham crackers and frosting were wasted in this project, as the students got a snack at the end,” he quipped. “We are open to any and all activities while we wait for the system to get fixed, and the students really enjoyed this unique experience.”

Above and below are some photo highlights from the students' welding experience using graham crackers and frosting!

Using graham crackers and frosting, the SPHS Metalworking students were asked to weld four different joint types: (clockwise from upper left) butt, lap, outside corner, and t-weld. Thanks to Mr. Pehrson for the photos!

SPHS metalworking students have a ‘tasty’ welding experience

October 10, 2025